Can energy-efficient coatings save thousands on utility bills? This question is crucial for businesses aiming to reduce operational costs and improve sustainability. Analyzing energy savings data from buildings using these coatings can uncover potential financial benefits and environmental impact. This article delves into the science, financial implications, and practical considerations of adopting energy-efficient coatings in the industry.

The Science Behind Energy-Efficient Coatings

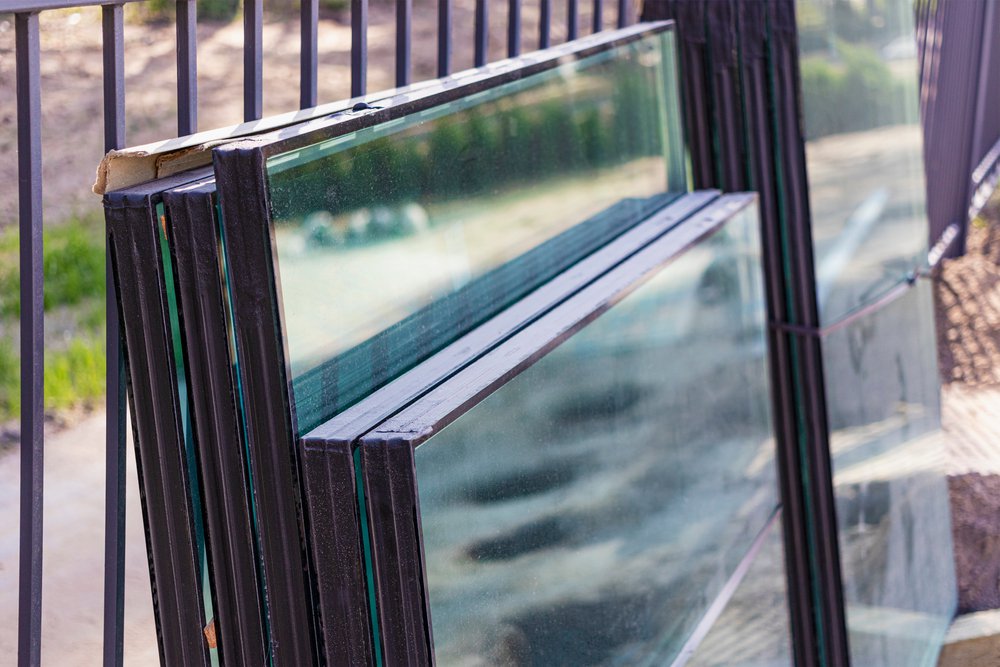

Energy-efficient coatings reduce heat transfer and enhance insulation. These coatings typically consist of low-emissivity (Low-E) materials that reflect infrared radiation while allowing visible light to pass through. This dual action minimizes heat gain in the summer and heat loss in the winter, leading to significant energy savings.

The primary materials used in these coatings include metal oxides and silver layers. Metal oxides, such as tin oxide or zinc oxide, are applied in thin layers to the glass surface. These materials have high reflectivity and low emissivity, which are crucial for thermal performance. Silver layers, often used in combination with metal oxides, further enhance the coating's ability to reflect infrared radiation.

The application process involves sputtering or chemical vapor deposition. Sputtering deposits thin films of metal oxides onto the glass in a vacuum chamber, ensuring uniform coverage. Chemical vapor deposition, on the other hand, uses chemical reactions to form a solid film on the glass surface. Both methods ensure the coatings are durable and effective.

Long-Term Financial Impacts and ROI

Investing in energy-efficient coatings offers substantial long-term financial benefits. Initial installation costs may seem high, but the return on investment (ROI) justifies the expense. Studies show that buildings with energy-efficient coatings can reduce energy consumption by up to 30%. This translates to significant savings on utility bills over time.

For example, a commercial building spending $100,000 annually on energy could save $30,000 each year. Over a decade, these savings accumulate to $300,000, far outweighing the initial installation costs. Additionally, energy-efficient coatings can increase property value. Buildings with lower operational costs are more attractive to buyers and tenants, enhancing marketability.

Industry data supports these projections. According to the U.S. Department of Energy, energy-efficient coatings can achieve payback periods of 3-5 years. This quick ROI makes them a viable option for businesses looking to improve energy efficiency. Furthermore, expert forecasts predict that as energy prices rise, the financial benefits of these coatings will become even more pronounced.

Environmental and Regulatory Benefits

Energy-efficient coatings offer significant environmental benefits. By reducing energy consumption, these coatings lower greenhouse gas emissions. This contributes to a smaller carbon footprint for buildings. According to the Environmental Protection Agency (EPA), buildings account for 39% of total U.S. energy use and 38% of carbon dioxide emissions. Implementing energy-efficient coatings can help mitigate these impacts.

Regulatory incentives further enhance the appeal of energy-efficient coatings. Governments and local authorities offer various incentives to promote energy efficiency. For instance, the U.S. Department of Energy provides tax credits and rebates for buildings that meet specific energy performance criteria. These incentives can offset installation costs, making the investment more attractive.

Several standards and certifications also support the use of energy-efficient coatings. The Leadership in Energy and Environmental Design (LEED) certification, for example, awards points for energy-efficient building materials. Achieving LEED certification can increase a building's market value and attract environmentally conscious tenants. Additionally, the International Energy Conservation Code (IECC) sets minimum efficiency standards for buildings, encouraging the adoption of energy-efficient technologies.

Making the Switch: Practical Considerations

Switching to energy-efficient coatings requires careful planning. For window manufacturers, selecting the right type of coating is crucial. Low-E coatings come in various forms, such as hard-coat and soft-coat. Hard-coat Low-E is more durable and suitable for single-pane windows, while soft-coat Low-E offers better performance for double-pane windows. Understanding these differences helps in making an informed choice.

Glazing contractors should focus on proper installation techniques. Ensure the glass surface is clean and free of contaminants before applying the coating. Use high-quality application tools to avoid defects. Proper sealing is also essential to maintain the coating's effectiveness. Training staff on these techniques can improve installation quality and customer satisfaction.

Cost considerations are another important factor. While energy-efficient coatings may have higher upfront costs, the long-term savings on utility bills and maintenance can offset these expenses. Evaluate the total cost of ownership, including installation, maintenance, and potential energy savings. This comprehensive approach provides a clearer picture of the financial benefits.

Supplier selection plays a key role in the success of the switch. Choose suppliers with a proven track record in energy-efficient coatings. Look for certifications and customer reviews to gauge reliability. Establishing a strong relationship with a reputable supplier ensures consistent quality and support. This partnership can also provide access to the latest advancements in coating technology.

The Future of Energy-Efficient Coatings in the Industry

Energy-efficient coatings offer substantial benefits, from significant utility bill savings to environmental advantages and regulatory incentives. As the industry evolves, their importance will only grow, making them a crucial component in building design and energy management. Visit Insul-Lite Manufacturing™ to explore different glass coatings that can make a difference in your building projects.