The IG manufacturing process plays a crucial role in creating energy-efficient, durable, and high-performance insulated glass (IG) units. As the demand for sustainable building materials increases, the need for precision in the IG manufacturing process is greater than ever. Whether you're a window distributor, glass manufacturer, or building contractor, understanding each step of this process can help you make informed decisions when selecting the right IG products for your projects.

In this article, we’ll walk through each stage of the IG manufacturing process—from raw material selection to final assembly. By the end, you’ll understand the craftsmanship and innovation that go into producing high-quality insulated glass.

Raw Material Selection

The IG manufacturing process begins with the careful selection of raw materials. These materials include float glass, desiccants, and sealants—all crucial in ensuring the final product’s performance. Float glass is typically the starting point, chosen for its high clarity and strength. It’s essential that the glass is free from impurities, as any imperfections could affect the IG unit’s insulating properties.

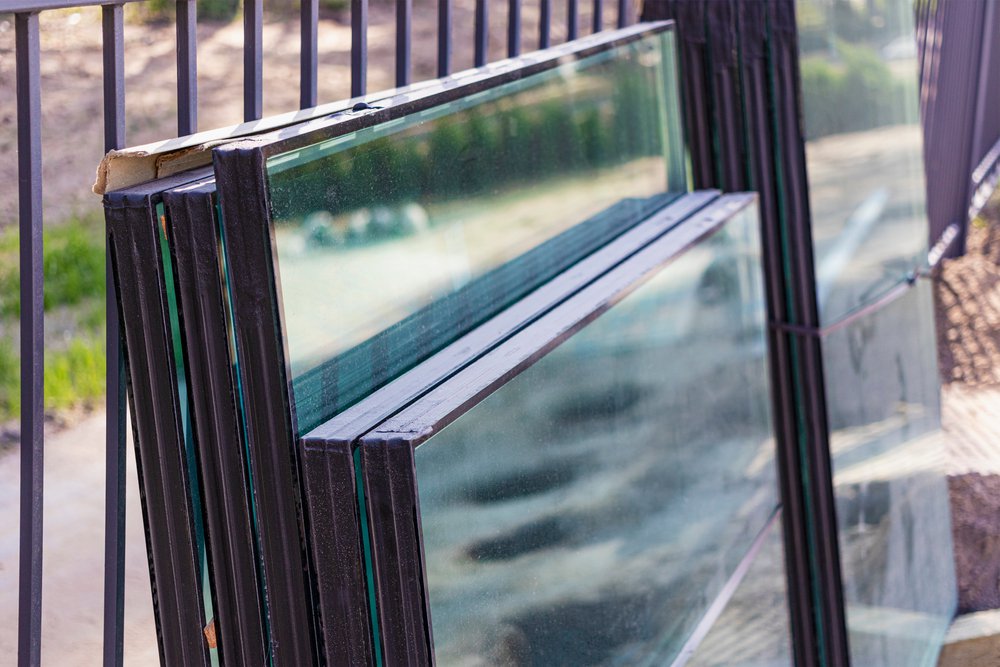

Sealants and spacers are also critical to the IG manufacturing process. The spacers, usually made of aluminum or stainless steel, separate the two glass panes, creating an insulating air space. This space can be filled with gases like argon or krypton to enhance insulation. Sealants, applied around the edges, ensure that the air space remains airtight and prevents moisture from entering.

Cutting and Sizing

Once the raw materials are selected, the next step in the IG manufacturing process is cutting and sizing the glass. Precision cutting machines are used to cut large sheets of float glass into specific sizes, depending on the project requirements. This step requires meticulous accuracy, as even a small miscalculation can lead to inefficiencies or waste.

The glass is cut in a controlled environment to prevent contamination and maintain its structural integrity. Special attention is given to the edges, which must be smooth and free of chips or cracks to ensure proper sealing during the assembly phase.

Washing and Cleaning

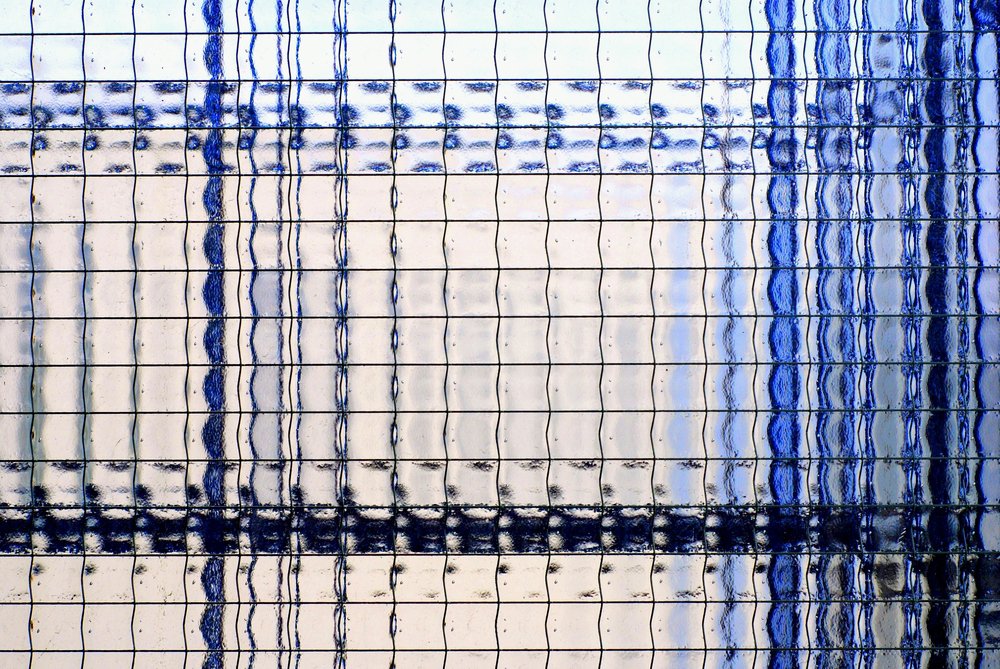

The washing and cleaning of glass is a pivotal step in the IG manufacturing process. Any debris, dust, or oil present on the glass surface can compromise the adhesion of the sealants, leading to air or moisture leaks over time. Automated washing machines, equipped with brushes and high-pressure water, clean the glass thoroughly.

After washing, the glass is dried and inspected for any remaining contaminants. High-quality IG manufacturers invest in advanced cleaning systems that guarantee spotless, residue-free glass, ensuring a perfect bond between the glass and the sealants in later stages.

Spacer Application

In the IG manufacturing process, spacers are applied between the glass panes to create an insulating air gap. The width of the spacer determines the thickness of the air space, which directly affects the IG unit's thermal performance. Spacers can be filled with a desiccant material to absorb any moisture that may be trapped within the air gap.

There are several types of spacers, including aluminum space bars, stainless steel, and newer warm-edge technology spacers that minimize thermal bridging. The choice of spacer depends on the desired thermal efficiency and the specific application of the insulated glass unit.

Filling the Insulating Space with Gas

To enhance the energy efficiency of the IG unit, the insulating air space between the glass panes is often filled with inert gases such as argon or krypton. These gases have lower thermal conductivity than air, which improves the unit’s ability to reduce heat transfer.

This gas-filling step in the IG manufacturing process is done with precision equipment that ensures a consistent and even distribution of the gas throughout the air space. The proper filling of the gas chamber is essential for maximizing the thermal performance of the final product.

Sealing the Unit

Once the gas has been filled into the air space, the unit is sealed with a high-performance sealant. This step is critical to ensure the long-term durability and efficiency of the IG unit. Double-sealing techniques are commonly used, with one seal providing structural integrity and the other serving as a moisture barrier.

The quality of the sealant and the precision of its application play a significant role in the lifespan of the IG unit. A well-sealed unit can last for decades without showing signs of condensation or fogging, common issues that arise when moisture penetrates the air gap.

Final Inspection and Testing

Before the IG unit is ready for installation, it undergoes rigorous inspection and testing as part of the IG manufacturing process. This stage includes checks for visual defects, dimensional accuracy, and overall performance. Advanced testing equipment is used to measure the unit's thermal efficiency, ensuring it meets industry standards.

Some manufacturers also test their IG units for durability by subjecting them to extreme temperature changes and humidity conditions. This ensures that the units can withstand the varying environmental factors they’ll face once installed in real-world applications.

Innovation and Sustainability in the IG Manufacturing Process

In recent years, innovation in the IG manufacturing process has led to the development of even more energy-efficient and environmentally friendly products. Insul-Lite Manufacturing™ is at the forefront of this movement, employing cutting-edge technologies and sustainable practices in every step of the process. A commitment to reducing waste, optimizing energy efficiency, and utilizing recyclable materials ensures that every IG unit not only performs exceptionally well but also aligns with modern sustainability goals.

Why Choose High-Performance IG Units?

The IG manufacturing process is a complex, multi-step journey that transforms raw materials into high-performance insulated glass units. From selecting the finest materials to precision cutting, gas filling, and sealing, each stage requires expertise and attention to detail. For window distributors, glass shop owners, and contractors, understanding this process is key to choosing the best products for your projects.

At Insul-Lite Manufacturing™, precision, quality, and sustainability are at the core of everything we do. Our IG units are designed to provide superior energy efficiency, durability, and long-term performance. Whether you’re looking for standard or custom solutions, we’re committed to delivering the highest level of craftsmanship in every unit we produce.

For more information about our products, or to learn how our insulated glass units can benefit your next project, visit our website or schedule a call today.